|

Die Attach Process

Die Attach

(also known as Die Mount or Die Bond) is the process of

attaching the

silicon chip to the

die pad or die cavity of the support structure (e.g., the

leadframe)

of the semiconductor package. There are two common die attach processes, i.e.,

adhesive die attach

and eutectic

die attach.

Both of these processes use

special die attach equipment and

die attach tools

to mount the die.

Adhesive Die Attach

Adhesive die attach uses

adhesives such as

polyimide, epoxy and silver-filled glass as die attach material to mount the die on the die pad

or cavity. The adhesive is first dispensed

in controlled amounts on the die pad or cavity. The die for mounting is

then ejected from the wafer by one or more ejector needles.

|

|

Fig. 1.

Two

examples of die attach machines |

While being ejected, a pick-and-place tool commonly known as a 'collet'

then retrieves the die from the wafer tape and positions it on the

adhesive. All of the above steps are done by special die attach

equipment or 'die bonders' (see Fig. 1).

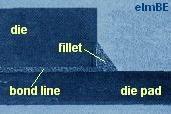

The mass of

epoxy climbing the edges of the die is known as the

die attach

fillet.

Excessive die attach fillet may lead to die attach

contamination

of the

die surface. Too little of it may lead to

die lifting

or die

cracking.

Another

critical aspect of adhesive die attach is the

ejection

of the die from the wafer tape during the pick-and-place system's

retrieval operation. The use of

inappropriate

or

worn-out

ejector needle and

improper

ejection parameter settings can cause die backside

tool marks

or

microcracks

that can eventually lead to

die cracking.

|

|

Fig. 2.

Photo

showing the D/A adhesive as the grainy material between the die and the

die pad |

See also:

Die Attach Failures

Eutectic Die Attach

Eutectic die

attach, which is commonly employed in hermetic packages, uses a

eutectic

alloy

to attach the die to the cavity. A eutectic alloy is an alloy with the

lowest

melting point possible for the metals

combined in the alloy. The Au-Si eutectic alloy is the most commonly used

die attach alloy in semiconductor packaging.

A gold

preform is placed on

top of the cavity while the package is being heated. When the die is

mounted over this gold preform, Si from the die backside

diffuses into

the gold preform, forming Au-Si alloy. As more Si diffuses into

the gold preform, the Si-to-Au ratio of the alloy increases, until such

time that the eutectic ratio is achieved. The Au-Si eutectic alloy has

2.85% of Si and melts at

about

363 degrees C.

Thus, the die attach temperature must be reasonably higher than this

temperature to achieve the eutectic melting point. At this point, the

alloy melts, attaching the die to the cavity.

To optimize

the die attachment, the operator

'scrubs'

the die into the eutectic alloy for

even distribution of the die attach alloy. Eventually the diffusion of

silicon atoms into the gold preform exceeds the eutectic limit, and the

die attach alloy begins to solidify once again. The package is then allowed

to cool down to completely solidify the eutectic alloy and complete the die attach

process.

Aside from

the Au-Si alloy, semiconductor assembly may employ other metal alloys

for eutectic die attach. Table 1 lists some of the other

alloys used in eutectic die attach preforms.

Table 1.

Compositions and Melting Points of some Eutectic Die Attach Preforms

|

Composition |

Temperature (deg C) |

|

Liquidus |

Solidus |

|

80% Au,

20% Sn |

280 |

280 |

|

92.5% Pb,

2.5% Ag, 5% In |

300 |

- |

|

97.5% Pb,

1.5% Ag, 1% Sn |

309 |

309 |

|

95% Pb,

5% Sn |

314 |

310 |

|

88% Au,

12% Ge |

356 |

356 |

|

98% Au,

2% Si |

800 |

370 |

|

100% Au |

1063 |

1063 |

Effects of Die Attach Voids

Regardless of

die attach process, the presence of voids in the die attach material

affects the quality and reliability of the device itself. Large die

attach voids result in low shear strength and low thermal/electrical

conductivity, and produce large

die stresses

that may lead

to

die cracking.

Small voids provide sufficient shear strength and electrical/thermal

conductivity, while 'cushioning' large dice from stresses. Total

absence of voids may mean high strength, but it may also induce large

dice to crack. The strength of die attachment is measured using the

die shear test.

|

Figure 3.

X-ray photo of large epoxy die attach voids; Au-Si eutectic voids are

more visible during x-ray inspection

because of the higher density of Au-Si

|

Front-End Assembly

Links:

Wafer Backgrind;

Die Preparation;

Die Attach;

Wirebonding;

Die Overcoat

Back-End Assembly

Links:

Molding;

Sealing;

Marking;

DTFS;

Leadfinish

See Also:

Die Shear Testing; Die

Attach Tools; Die

Attach Materials;

Die Attach Failure Mechanisms;

IC

Manufacturing; Assembly Equipment

HOME

Copyright

©

2001-2006

www.EESemi.com.

All Rights Reserved.

|