|

Ball Grid Array (BGA)

Ball Grid Array,

or

BGA,

is a

surface-mount package that utilizes an array of metal spheres or balls

as the means of providing external electrical interconnection, as

opposed to the pin-grid array (PGA) which uses an array of leads for

that purpose. The balls are composed of solder, and are attached

to a laminated substrate at the bottom side of the package. The die of the BGA is connected to the substrate either by

wirebonding or

flip-chip

connection. The substrate of a BGA has internal conductive traces

that route and connect the die-to-substrate bonds to the substrate-to-ball array

bonds.

The main

advantage of BGA as a packaging solution for integrated circuits is its

high interconnection density, i.e., the number of pins (or balls,

rather) that it offers per given package volume is high. A related

advantage arising from this high I/O density is its small board space

occupation.

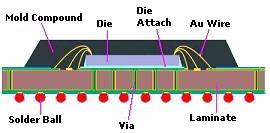

Figure 1.

Examples of BGA packages; the leftmost photo is a top view image

In addition,

assembly of BGA onto circuit boards is more manageable in comparison to

its leaded counterparts of the same pin count, mainly because the solder

needed for board mounting already come from the solder balls themselves,

which are factory-applied in precise form and size during the assembly

of BGA itself. Balls also tend to

'self-align'

to their attachment sites during board mounting.

The BGA is

attached to the circuit board using a reflow oven, which melts the

solder balls. The solder balls are already

matched in position with their respective attachment sites on the

circuit board as this happens. The surface tension of the molten solder

ball keeps the package aligned in its proper location on the board, until the

solder cools and solidifies. Good control of the board soldering

process and temperature is required to prevent the solder balls from

shorting with each other.

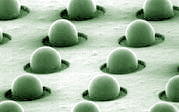

Figure 2.

Cross-section of a wirebonded PBGA package

Another

advantage offered by BGA is the lower thermal resistance between itself

and the circuit board due to the following reasons: 1) the relatively short distance between them;

2) the excellent thermal properties of the substrate; and 3) the use of

thermally-enhancing features such as thermal vias within the substrate

and thermal balls under it. These allow the heat generated by the device inside the BGA to flow more

freely to the board, resulting in better heat dissipation for the device

that helps keep it from overheating.

The shorter

path provided by the BGA between the die and the circuit board also

leads to better electrical performance, since the shorter path

introduces lesser inductance, in effect minimizing distortion of signals

in high speed applications. Power and ground planes may also be

designed into the substrates to reduce ground and power inductance.

All packages

have drawbacks, and the BGA is no exception. Its disadvantages

include: 1) the inability of the solder balls to flex, such that

thermo-mechanical and flexural stresses from the circuit board can

easily be transmitted to the package and its joints, leading to

potential reliability issues; and 2) the difficulty of inspecting the

balls and solder joints for defects once the BGA has been soldered onto

the board.

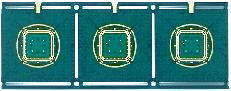

Figure 3.

Solder Balls on a BGA package

Plastic ball

grid array (or PBGA), is a type of BGA that either has a plastic-molded

or glob-top encapsulated body. It was originally developed by Motorola

in the late 1980's for applications with space and weight limitations.

PBGA body sizes range from 7 to 50 mm, with ball pitches of 1.00, 1.27,

and 1.50 mm. PBGA pin counts, as of this writing, range from 16 to 2401

pins.

The laminated substrate

of a PBGA is usually composed of glass-reinforced organic material that

has excellent thermal properties (high Tg, high temperature stability,

and low heat resistance), such as Bismaleimide-Triazine (BT).

The conductive traces within the substrate are usually in the form of

etched copper foils bonded to it.

The assembly of PBGA's is usually

accomplished on a per substrate strip basis, with each strip holding

several package sites.

Figure 4.

Example of a strip of future BGA packages

A die is

attached to every die pad or flag on the substrate strip, and then

electrically connected to its substrate's routers either by wirebonding

or through the bumps on its bond pads is

flip chip connection is

employed. The die and wires are then encapsulated either by cavity

molding with epoxy molding compound or by glob-topping with a liquid encapsulant. The glob-top material is usually contained to its

specific form and volume with a dam.

After

encapsulation, solder ball preforms are placed on the solder pads of the

bottom surface of the substrate strip, which are then reflowed to form

the final solder balls under the PBGA package. Once the solder balls

have been formed, the packages are singulated from the strip either by shearing

with a carbide-tipped tool, by routing with a programmable router, or by

cutting with a diamond wheel.

Figure 5.

Example of an automated

routing

machine for singulating BGA's

See Also:

PBGA;

CBGA; FPBGA or FBGA;

LFBGA;

TFBGA; VFBGA;

Die Attach;

Wirebonding;

Molding;

Sealing;

Marking;

Flip Chip

Assembly; TAB Assembly;

IC

Manufacturing;

Assembly Equipment;

Solder Paste Printing

HOME

Copyright

© 2004

www.EESemi.com.

All Rights Reserved.

|