Die Lifting

Die lifting

is the disbonding or detachment of the die from its die pad or die

cavity. A die

that undergoes

die lifting is commonly referred to as a

'lifted die'.

Die lifting

mechanisms

may be

classified into

three

types: 1) die lifting caused by a fracture within the die attach

material itself (cohesion failure); 2) die lifting due to delamination

between the die backside and the die attach material (adhesion failure);

or 3) die lifting due to delamination between the die attach material

and the die pad or cavity (adhesion failure).

Determining which of these mechanisms is predominant in a die

lifting issue is important in preventing its recurrence.

Excessive

voids, insufficient fillet formation, and inadequate bond line thickness

lower

the

fracture strength

of the die attach material,

which can lead to its

cohesion failure

once the unit is

subjected to thermo-mechanical stresses. When this happens, the die

attach material fractures in the middle and results in die lifting, leaving die attach material

still sticking on both the die backside and the die pad. The

degradation of the mechanical strength of the die attach material can

also be due to: 1) contamination; 2) chemical degradation with time; and

3) chemical degradation from external factors, e.g., moisture,

temperature, etc.

|

|

|

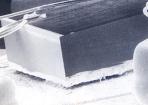

Figure 1.

SEM photo of a lifted die

caused by

insufficient die attach fillet

|

Adhesion

failures

can also be

caused by the aforementioned issues, i.e.,

excessive die attach voids, insufficient fillet formation, inadequate

bond line thickness, and die attach material problems.

However, they are also frequently encountered when contaminants are

present on the attachment surface. Thus, contaminants

on the die backside can lead to die attach-to-die delamination, while contaminants

on the die pad can lead to die attach-to-die pad

delamination. Either way, the resulting delamination can lead to die

lifting. Eutectic die attach delaminations may also be due to inadequate scrubbing, incorrect preform

size, and improper equipment settings.

Inadequate

die attach fillet formation and

excessive

die attach voids act as

stress concentrators

that can also result in contiguous cracks at the backside of the die, especially in units that

use eutectic die attach. These cracks can propagate to a point wherein

the upper part of the die is separated from the bottom part. If the

bottom part of the die is still attached to the die attach system, then

this, technically, is still a

die cracking

problem

(not die

lifting),

although extreme cases indeed give the impression that the die has

lifted off from its resting place.

Die Lifting

may be

accelerated by SHRT,

Temp Cycle, and Thermal Shock.

See also:

Package

Failure Mechanisms;

Die Crack FA

Flow;

Die Attach; Failure Analysis

HOME

Copyright

©

2005.

EESemi.com.

All Rights Reserved.