|

Chip-on-Board

(COB)

Chip-on-Board,

or

COB,

refers to the

semiconductor assembly technology wherein the microchip or die is

directly

mounted on and electrically interconnected to its final circuit

board, instead of undergoing traditional assembly or

packaging as an individual IC. The elimination of conventional device

packaging from COB assemblies simplifies the over-all process of

designing and manufacturing the final product, as well as improves its

performance as a result of the shorter interconnection paths.

The general

term for COB technology is actually

'direct chip attachment',

or

DCA.

Aside from circuit boards used for COB's, various

substrates

are available for use in DCA. There are, for instance, ceramic and

glass ceramic substrates which exhibit excellent dielectric and thermal

properties. Organic substrates that weigh and cost less while

providing a low dielectric constant also exist. There are also

flex substrates which, being pliable, have the ability to bend.

DCA assemblies have received a number of other names aside from 'COB'

based on these available substrates, e.g., chip-on-glass (COG),

chip-on-flex (COF), etc.

The

COB process

consists of just three major

steps:

1) die attach or die mount; 2) wirebonding; and 3) encapsulation of the

die and wires. A variant of COB assembly, the

flip-chip on

board (FCOB), does not require wirebonding since it employs a chip whose

bond pads are bumped, which are the ones that connect directly to

designated pads on the board. As such, FCOB's have their chips

facing downward on the board (hence the name 'flipchip'). Aside

from encapsulation, it is also necessary to

'underfill'

a flip chip

to protect its active surface and bumps from thermo-mechanical and

chemical damage.

|

|

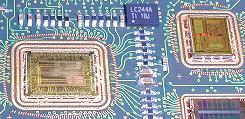

Figure 1.

Example of a

Chip-on-Board (COB) Assembly; note that the chips are

directly wirebonded to the PCB |

Die attach

basically consists of applying a die attach adhesive to the board or

substrate and mounting the chip or die over this die attach material.

Adhesive

application

may be in the

form of dispensing, stencil printing, or pin transfer.

Die placement

must be accurate enough to ensure proper orientation and good planarity

of the die. This is followed by a

curing

process (such

as exposure to heat or ultraviolet light) that allows the adhesive

to attain its final mechanical, thermal, and electrical properties.

After curing, organic contaminants must be removed either by

plasma

or

solvent

cleaning

so as not to

affect the wirebonding process.

The

wirebonding

process is

similar to that used in traditional semiconductor assembly, i.e., thermosonic

Au or Cu

ball bonding

or ultrasonic

Al

wedge bonding

may be employed to connect wires between the die and the board or

substrate. Chip-to-chip wirebonding may also be done for COB assembly.

Needless to say, the bond pads of the die and the board or substrate

must be free of any contaminants and defects to ensure the formation of

good and reliable bonds.

Finally, the die and bond

wires are

encapsulated

to protect them from mechanical and chemical

damage. Encapsulation is generally done by dispensing a liquid

encapsulant material (usually epoxy-based) over the die and wires or by

transfer molding. Encapsulants

also need to undergo curing, the process of which depends on the type of

encapsulant used.

Advantages

offered by COB technology include: 1) reduced space requirements; 2)

reduced cost; 3) better performance due to decreased

interconnection lengths and resistances; 4) higher reliability due to

better heat distribution and a lower number of solder joints; 5) shorter

time-to-market; and 6) better protection against reverse-engineering.

See Also:

Die Attach;

Wirebonding;

Molding; TAB Assembly;

Flip Chip;

IC

Manufacturing;

Assembly Equipment

HOME

Copyright

©

2005

www.EESemi.com.

All Rights Reserved.

|