System in a

Package (SIP)

The term

“System in a Package”

or SIP

refers to a semiconductor device that incorporates multiple chips that

make up a complete electronic system into a single package.

Electronic devices like mobile phones conventionally consist of several

individually packaged IC's handling different functions, e.g. , logic

circuits for information processing, memory for storing information, and

I/O circuits for information exchange with the outside world. In a

System-in-a-Package, all of these individual chips are assembled into a

single package, allowing tremendous space savings and significant

down-sizing of electronic gadgets.

SIP must not

be confused with SOC,

or System-on-a-Chip, which is a complete electronic system built on a

single chip. SOC's suffer from long development time and high

development costs, mainly because it is difficult to make an entire

system of differently functioning circuit blocks work on a single

chip. SIP technology, on the other hand, simply takes several readily

available chips and put them together in a single package.

The

predecessor of the SIP is the multichip module (MCM) of the early

1990's, wherein several specialized chips are also assembled in a single

ceramic package as a system solution using traditional assembly

processes. Some people consider the SIP and the MCM as still the

same thing, but most people prefer to give SIP its own distinct identity

because of its mass-production nature and use of cutting edge assembly

technologies. For instance, the chips in an MCM are mounted on the same

plane (the cavity substrate), whereas SIP employs die stacking as its

natural configuration.

Figure

1. Example of an MCM, the predecessor of the SIP

The ability

to take existing chips to come up with a totally new system in a single

package has one clear advantage: it drastically reduces development time

and risk to bring new products to the market more quickly. With SIP

technology, vendors are able to cram multiple flash devices, SRAMs,

DRAMs, microcontrollers, ASICs, DSPs, and passive components into very

thin packages that can fit into sleeker, more stylish, and yet more

complex electronic gadgets.

Aside from

shorter time-to-market, SIP manufacturing reduces its over-all assembly

and test costs, since only one package will be assembled and tested to

come up with the system. Better electrical performance is also

achieved because of the shorter interconnections within the SIP. SIP's

also simplify the process of assembling the final application module by

requiring simpler PCB lay-outs, since the complex interconnections

required by the system have already been taken care of inside the SIP.

The challenge

in SIP manufacturing lies in the assembly process itself. Touted

as the next-level multi-chip module (MCM) assembly technology, it

requires the ability to assemble and interconnect several die not only

horizontally (wherein die are placed side by side), but vertically as

well (wherein several die are placed on top of each other).

Mounting die

on top of each other and interconnecting them is known as

die stacking,

a new technology that is harnessed extensively in state-of-the-art SIP

manufacturing. This extensive use of stacked die configuration is

the reason why SIP is also known as the 3-D package.

One challenge

posed by die stacking is the need to keep the stack thermally and

mechanically stable on the substrate, while allowing good

interconnection among the die, and keeping the package as thin as

possible in doing so. Needless to say, package thickness largely

depends on the number of die that are vertically stacked inside.

For instance, current technology would generally require a 1.4-mm

chip scale package (CSP)

to accommodate a six-die stack whereas a four-die stack can fit within a

1.2-mm CSP.

For more

details about die stacking, please see the article:

Die Stacking.

Flip chip

bonding is also used in SIP interconnection, either on its own or as a

complement to wirebonding. Flip chip configuration may be applied

either to the upper die or the lower ones, depending on the intent of

the design. Flip chipping a bottom die directly onto the substrate

enables that die to operate at a high speed. On the other hand,

flip chipping a top die eliminates the use of long wires for connection

to the substrate.

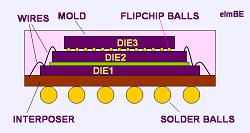

Figure

2. Example of a 3-die SIP

configuration employing

both

wirebonding and flip chip bonding

Heat dissipation is another challenge in the development of SIP's.

Taking chips off-the-shelf and using them in SIP's isn't always easy

from the thermal point of view, since these chips were designed to

dissipate heat through their own packages. Crowding them all

together inside a SIP can accumulate enough heat to be of major concern

in the field. Thermal management is therefore an important ingredient of

any SIP development process.

SIP

manufacturing not only offers assembly challenges, but test challenges

as well. SIP's combine microelectromechanical systems,

optoelectronic devices, various sensors, linear and digital circuits,

etc., which were built on a different wafer fab process technologies and

therefore have varying excitation requirements. Add to this the

fact that each of these system blocks require special test methods of

its own. A test solution to meet the various test resources and

methods required by a complex SIP can turn out to be expensive.

For these

test issues, some quarters propose a cost-effective solution in the form

of an open-architecture automated test equipment (OA-ATE) that allows

semiconductor manufacturers to specify their own test resource and

instrumentation requirements. 'Specialization' of test capability

nonetheless require some standardized vital elements: 1)

an

industry-standard bus structure; 2) compatibility with industry-standard

data formats; 3) browser technology to access and control

resources; 4) a modular hardware and software structure to enable

reconfigurability; and 5) partitioned test supported by ATE and EDA

tools.

Successful

implementation of SIP manufacturing brings in many advantages that are

important to the semiconductor industry of the future: shorter

time-to-market, lower cost, flexibility, smaller size, etc. To get

there, however, requires a monumental engineering effort to address all

technical obstacles along the way.

See Also:

System-on-a-Chip;

Flip Chip

Assembly; Chip Scale Package;

IC Packaging;

IC

Manufacturing

HOME

Copyright

© 2001-2005

www.EESemi.com.

All Rights Reserved.