Focused Ion

Beam

Focused

Ion Beam (FIB) techniques are used in a variety of applications.

In terms of failure analysis, FIB techniques are commonly used in

high magnification

microscopy, die surface

milling or

cross-sectioning,

and even

material deposition.

A

FIB system works very similarly to a scanning electron microscope,

except that it uses a

finely focused beam of gallium (Ga+)

ions

instead

of the latter's use of electrons.

This focused primary beam of gallium ions is rastered on the

surface of the material to be analyzed.

As it hits the surface, a small amount of material is

sputtered,

or dislodged, from the surface.

|

|

Fig.

1.

Examples of

Focused Ion Beam (FIB) Stations

|

The

dislodged material may be in the form of secondary ions,

atoms, and

secondary

electrons. These

ions, atoms, and electrons are then collected and analyzed as signals to

form an image on a screen as the primary beams scans the surface.

This image forming capability allows high magnification

microscopy.

The

higher the primary beam current, the more material is sputtered from the

surface. If only high-mag

microscopy

is intended, only a

low-beam operation must be employed.

High-beam operation is used to sputter or remove material from

the surface, such as during high-precision milling or cross-sectioning

of an area on the die.

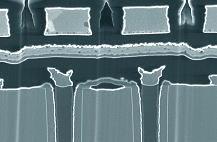

Fig.

2.

Cross-section

of a DRAM cell produced by FIB

A

FIB system can also bombard an area on the die with various

gases as it

performs primary beam sputtering. Depending on the gases used, these gases can react with the

primary beam to either

etch

material from or

deposit

material onto the surface.

See Also:

Failure

Analysis; All

FA Techniques;

Sectioning;

Die

Deprocessing;

SEM/TEM; FA Lab

Equipment; Basic FA

Flows;

Package Failures; Die

Failures

HOME

Copyright

© 2001-2005

www.EESemi.com.

All Rights Reserved.