Finite Element

Analysis (FEA)

Finite Element Analysis (FEA)

is a computer-based numerical technique for obtaining near-accurate

solutions to a wide variety of complex engineering problems where the

variables are related by sets of algebraic, differential, and integral

equations.

Its applications include estimation or prediction of

structural strength and behavior, modeling, simulation, and design optimization in

engineering branches such as solid mechanics, fluid mechanics,

thermodynamics, electromagnetics, acoustics, and the like.

State-of-the-art FEA can now be applied to highly non-linear problems

involving convoluted geometries, inelastic material dynamics, and

fluctuating process conditions.

Finite Element Analysis operates on the principle that the analysis of a

large and complex structure can be simplified by breaking down the

complex structure into its parts, or "elements". Each of these

elements are then described by a set of relatively simpler equations.

These element-specific sets of equations are then joined together to

come up with an extremely large set of inter-related equations that

describe the behavior of the entire structure.

A computer is then used to perform the number crunching needed to find

solutions to these equations, producing plots to graphically show how

the structure behaves against the various excitation or stress

conditions of interest.

|

|

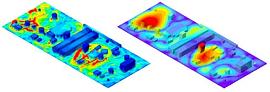

Figure 1.

Examples of FEA plots generated from board stress analyses conducted by

Everett Charles Technologies; source: www.ectinfo.com |

It is

said that the use of finite elements to analyze more complex things

started as early as over 2,000 years ago, when geometers interested in

determining the circumference and area of a circle split the circle into

small rectangles that approximately described the area of the circle.

Eventually this allowed the determination of the value of pi.

FEA now makes possible the

prediction of how a certain design will measure up against

specifications even before a prototype is built, allowing quick

improvements to the design if necessary. FEA also prevents the

high costs of over-designing a structure, since it provides solutions

that are accurate enough to forego of whatever design guardbands were

being put in place just a few decades ago.

Finite

Element Analysis capability is

not cheap.

It needs powerful hardware and software for its effective execution. Commercial FEA software used in the semiconductor industry can

cost tens of thousands of dollars. Furthermore, engineers who are tasked to

perform FEA must have a strong foundation in engineering mechanics and

should have a basic understanding of finite element

methods. ANSYS and ALGOR are examples of companies that sell FEA

software.

Still,

companies who can afford to set up FEA capability should do so, because

the system cost will be negligible compared to failures that may arise

from inadequate design or modeling capability. Prevention of

costly over-designs will also help pay for the FEA system.

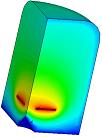

Figure 2.

3-D FEA plots showing how a beam of a micromachined

electromechanical system (MEMS) would behave under different excitation

frequency

levels; source: www.algor.com

FEA

is used extensively in the

semiconductor industry. 'Real-life' examples

of FEA applications in the industry include but are not limited to the

following:

- continuous

improvement of IC package designs and material sets;

- stress analysis of

adhesive bonding and design of bonded joints;

- fracture mechanics and

fatigue analysis of adhesive bonds;

- thermal

stress and

deformation analysis of solder joints;

- fracture mechanics of

solder joints for solder joint reliability studies;

-

thermo-mechanical stress analysis of interfaces within a package;

- comparative

analyses between flip-chip and wirebonded package configurations;

- thermal,

mechanical, and electrical modeling for various leadframe designs and

materials;

- simulations

of wirebond and die attach fatigue failures;

- selection

of the correct wire diameter, arrangement and profile given the current

loads;

- reduction of wafer

backside waviness through soft pad wafer backgrinding;

- modeling of the vibration

responses of beams in micro-machined silicon accelrometers; etc.

|

|

Figure 3.

An FEA contour plot of the electric field surrounding a TIP field emitter; source:

www.ansys.com

|

See Also:

IC Packaging

HOME

Copyright

© 2004

www.EESemi.com.

All Rights Reserved.