Hot Carriers

The term

'hot carriers'

refers to either holes or electrons (also referred to as

'hot

electrons')

that have gained very high kinetic energy after being accelerated by a strong

electric field in areas of high field intensities within a semiconductor

(especially MOS) device. Because of their high kinetic energy, hot carriers can get injected and trapped in areas of the

device where they shouldn't be, forming a space charge that causes the

device to degrade or become unstable. The term

'hot carrier effects',

therefore, refers to device degradation or instability caused by hot

carrier injection.

According to

the 5th Edition Hitachi Semiconductor Device Reliability Handbook, there

are four (4) commonly encountered hot carrier injection mechanisms.

These are 1) the drain

avalanche hot carrier injection; 2) the channel hot electron injection; 3)

the substrate hot electron injection; and 4)

the

secondary generated hot electron injection.

The

drain

avalanche hot carrier (DAHC)

injection

is said to produce the worst device degradation under normal operating

temperature range. This occurs when a

high voltage

applied at the drain under non-saturated conditions (VD>VG) results in

very high

electric fields near the drain, which

accelerate channel carriers into the drain's depletion region. Studies

have shown that the worst effects occur when VD

= 2VG.

The

acceleration of the channel carriers causes them to collide with Si lattice atoms, creating dislodged

electron-hole pairs in the process. This phenomenon is known as

impact ionization,

with some of the displaced e-h pairs also gaining enough energy to

overcome the

electric potential barrier between the silicon substrate and the gate

oxide.

Under the influence

of drain-to-gate field, hot carriers

that surmount the substrate-gate oxide barrier get injected into the gate oxide layer where they are sometimes trapped. This hot

carrier injection process occurs mainly in a narrow injection zone at

the drain end of the device where the lateral field is at its maximum.

Hot carriers can be trapped at the Si-SiO2 interface (hence referred to

as 'interface states') or within the oxide itself, forming a

space charge (volume charge) that increases over time as more charges

are trapped. These trapped charges shift

some of the characteristics of the device, such as its

threshold

voltage

(Vth) and its

conveyed

conductance

(gm).

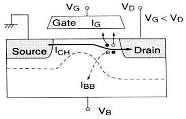

Figure 1.

DAHC injection involves impact

ionization of carriers near

the drain area; source: Hitachi

Semiconductor Reliability Handbook

Injected

carriers that do not get trapped in the gate oxide become

gate current.

On the other hand, majority of the holes from the e-h pairs generated by

impact ionization flow back to the substrate, comprising a large portion

of the

substrate's drift current.

Excessive substrate current may therefore be an indication of hot

carrier degradation. In

gross cases, abnormally high substrate current can upset the balance of carrier flow and facilitate

latch-up.

Channel hot

electron (CHE) injection

occurs when

both the gate voltage and the drain voltage are significantly higher

than the source voltage, with VG≈VD. Channel carriers that travel

from the source to the drain are sometimes driven towards the gate oxide

even before they reach the drain because of the high gate voltage.

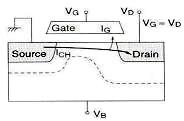

Figure 2.

CHE injection involves propelling of carriers in the

channel

toward the oxide even before they reach the drain area;

source: Hitachi Semiconductor Reliability Handbook

Substrate hot

electron (SHE) injection

occurs when

the substrate back bias is very positive or very negative, i.e.,

|VB|>>

0. Under this condition, carriers of one type in the substrate are

driven by the substrate field toward the Si-SiO2 interface. As they move

toward the substrate-oxide interface, they further gain kinetic energy

from the high field in surface depletion region. They eventually

overcome the surface energy barrier and get injected into the gate

oxide, where some of them are trapped.

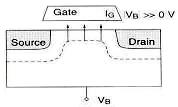

Figure 3.

SHE injection involves trapping of carriers from the

substrate;

source: Hitachi Semiconductor Reliability Handbook

Secondary

generated hot electron (SGHE) injection

involves the generation of hot carriers from impact ionization involving

a secondary carrier that was likewise created by an earlier incident of

impact ionization. This occurs under

conditions similar to DAHC, i.e., the applied voltage at the drain is

high or

VD>VG,

which is

the driving condition for impact ionization. The main difference,

however, is the influence of the

substrate's back bias in the hot carrier generation.

This back bias results in a field that tends to drive the hot carriers

generated by the secondary carriers toward the surface region, where

they further gain kinetic energy to overcome the surface energy barrier.

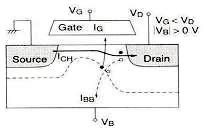

Figure 4.

SGHE injection involves hot carriers generated by secondary

carriers;

source: Hitachi Semiconductor Reliability Handbook

Hot carrier

effects are brought about or aggravated by reductions in device

dimensions without corresponding reductions in operating voltages,

resulting in higher electric fields internal to the device. Problems due

to hot carrier injection therefore constitute a major obstacle towards

higher circuit densities. Recent studies have even shown that voltage

reduction alone will not eliminate hot carrier effects, which were

observed to manifest even at reduced drain voltages, e.g., 1.8 V.

Thus,

optimum

design

of devices to minimize, if not prevent, hot carrier effects is the best

solution for hot carrier problems. Common design techniques for

preventing hot carrier effects include: 1) increase in channel lengths;

2) n+ / n-

double

diffusion

of sources and drains; 3) use of

graded

drain junctions; 4) introduction of self-aligned n- regions between the

channel and the n+ junctions to create an

offset

gate; and 5) use of

buried

p+ channels.

Hot carrier

phenomena are

accelerated

by low temperature, mainly because this condition reduces charge

detrapping.

A simple

acceleration model for hot carrier effects is as follows:

AF = R2 / R1

AF =

e([Ea/k]

[1/T1-1/T2] + C [V2-V1])

where:

AF = acceleration

factor of the mechanism;

R1 = rate at

which the hot carrier effects occur under conditions V1 and T1;

R2 = rate at

which the hot carrier effects occur under conditions V2 and T2;

V1 and V2 =

applied voltages for R1 and R2, respectively;

T1

and T2 = applied temperatures (deg K) for R1 and R2, respectively;

Ea = -0.2 eV to

-0.06 eV;

and C = a constant.

See

Also:

Die Failures; Failure Analysis; Reliability Models

HOME

Copyright © 2004

www.EESemi.com. All Rights

Reserved.