Crystalline

Defects in Silicon

Like

anything else in this world, crystals inherently possess imperfections,

or what we often refer to as

'crystalline defects'.

The presence of most of these crystalline defects is undesirable in

silicon wafers, although certain types of 'defects' are essential in

semiconductor manufacturing. Engineers in the semiconductor industry

must be aware of, if not knowledgeable on, the various types of silicon

crystal defects, since these defects can affect various aspects of

semiconductor manufacturing - from production yields to product

reliability.

Crystalline defects may be

classified into four categories according to their geometry.

These categories are: 1) zero-dimensional or

'point' defects;

2) one-dimensional or

'line' defects;

3) two-dimensional or

'area' defects;

and 4) three-dimensional or

'volume' defects.

Table 1 presents the commonly-encountered defects under each of these

categories.

Table 1.

Examples of Crystalline Defects

|

Defect Type |

Examples |

|

Point or

Zero-Dimensional Defects |

Vacancy Defects

Interstitial Defects

Frenkel Defects

Extrinsic Defects |

|

Line or

One-Dimensional Defects |

Straight Dislocations

(edge or screw)

Dislocation Loops |

|

Area or

Two-Dimensional Defects |

Stacking Faults

Twins

Grain Boundaries |

|

Volume or

Three-Dimensional Defects |

Precipitates

Voids |

There are

many forms of crystal

point defects. A defect wherein a silicon atom is missing from one of

these sites is known as a

'vacancy'

defect. If an atom is

located in a non-lattice site within the crystal, then it is said to be

an 'interstitial'

defect. If the

interstitial defect involves a silicon atom at an interstitial site

within a silicon crystal, then it is referred to as a

'self-interstitial'

defect. Vacancies and

self-interstitial defects are classified as

intrinsic point defects.

If an atom leaves its site

in the lattice (thereby creating a vacancy) and then moves to the

surface of the crystal, then it becomes a

'Schottky'

defect. On the other hand, an atom that vacates its position in

the lattice and transfers to an interstitial position in the crystal is

known as a

'Frenkel'

defect. The formation of a Frenkel defect therefore produces two defects

within the lattice - a vacancy and the interstitial defect, while the

formation of a Schottky defect leaves only one defect within the

lattice, i.e., a vacancy. Aside from the formation of Schottky and

Frenkel defects, there's a third mechanism by which an intrinsic point

defect may be formed, i.e., the movement of a surface atom into an

interstitial site.

Extrinsic

point defects,

which are point defects involving foreign atoms, are even more critical

than intrinsic point defects. When a non-silicon atom moves into a

lattice site normally occupied by a silicon atom, then it becomes a

'substitutional

impurity.'

If a non-silicon atom occupies a non-lattice site, then it is referred

to as an

'interstitial

impurity.'

Foreign atoms

involved in the formation of extrinsic defects usually come from dopants,

oxygen, carbon, and metals.

The presence

of point defects is important in the kinetics of diffusion and

oxidation. The rate at which diffusion of dopants occurs is

dependent on the concentration of vacancies. This is also true for

oxidation of silicon.

Crystal line

defects

are also known as

'dislocations',

which can be classified as one of the following: 1) edge dislocation; 2)

screw dislocation; or 3) mixed dislocation, which contains both edge and

screw dislocation components.

An

edge

dislocation

may be

described as an extra plane of atoms squeezed into a part of the crystal

lattice, resulting in that part of the lattice containing extra atoms

and the rest of the lattice containing the correct number of atoms.

The part with extra atoms would therefore be under compressive stresses,

while the part with the correct number of atoms would be under tensile

stresses.

The

dislocation

line

of an edge dislocation is the line connecting all the atoms at the

end

of the extra plane.

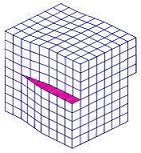

Figure 1.

An edge dislocation; note the insertion

of atoms in the upper part of the lattice

If the

dislocation is such that a step or ramp is formed by the displacement of atoms

in a plane in the crystal, then it is referred to as a

'screw

dislocation.'

The

screw basically forms the boundary between the slipped and unslipped

atoms in the crystal. Thus, if one were to trace the periphery of a

crystal with a screw dislocation, the end point would be displaced from

the starting point by one lattice space.

The

dislocation line

of a screw dislocation is the

axis

of the screw.

Figure 2.

A screw dislocation; note the screw-like

'slip' of atoms in the upper part of the lattice

If the

dislocation consists of an extra plane of atoms (or a missing plane of

atoms) lying entirely within the crystal, then the dislocation is known

as a

'dislocation loop.'

The

dislocation line of a dislocation loop forms a closed curve that is

usually circular in shape, since this shape results in the lowest

dislocation energy.

Dislocations

are generally undesirable in silicon wafers because they serve as sinks

for metallic impurities as well as disrupt diffusion profiles.

However, the ability of dislocations to sink impurities may be

engineered into a wafer fabrication advantage. i.e., it may be used in

the removal of impurities from the wafer, a technique known as

'gettering.'

Area defects

in crystals consist of stacking faults, grain boundaries, and twin

boundaries. A

'stacking

fault'

pertains to a

disturbance in the regularity of the stacking of planes of atoms in a

crystal lattice. This usually occurs when a plane is inserted into

or removed from the lattice. The insertion of an extra plane in the

stacking is known as an 'extrinsic' stacking fault, while the removal of

a plane is referred to as an 'intrinsic' stacking fault.

Stacking

faults can become electrically active when decorated by impurity atoms.

Electrically active stacking faults can cause device degradation,

examples of which are higher reverse bias currents in p-n junctions and

storage time reduction in MOS circuits.

Figure 1.

Photo of a Stacking Fault

Image Source:

http://lmass.uah.edu

- J. A.

Gavira-Gallardo, J. D. Ng and M.A. George

A

'twin'

is an area defect wherein a mirror image of the regular lattice is

formed during the growth of the silicon ingot, usually caused by a

perturbation. The

'twin boundary'

is the mirror plane of the twin formation.

A

'grain

boundary'

refers to the

transition or interface between crystals whose atomic arrangements are

different in orientation with respect to each other.

Volume defects

in a crystal

are also known as

'bulk'

defects,

which include

voids

and

precipitates

of extrinsic and intrinsic point defects.

Every

impurity introduced

into a crystal has a certain level of

solubility, which defines the

concentration of that impurity that the solid solution of the host

crystal can accommodate. Impurity solubility usually decreases

with decreasing temperature.

If an impurity is introduced into a crystal at the maximum

concentration allowed by its solubility at a high temperature, the

crystal will become

supersaturated with that impurity

once it is cooled

down. A crystal under such supersaturated conditions seeks and

achieves equilibrium by

precipitating

the excess impurity atoms into another phase of different composition or

structure.

Precipitates

are considered undesirable because they have been known to act as sites

for the generation of dislocations. Dislocations arise as a means

of relieving stress generated by the strain exerted by precipitates on

the lattice. Precipitates induced during silicon wafer processing

come from oxygen, metallic impurities, and dopants like boron.

See Also:

Crystal Defect Effects;

Incoming

Wafers;

Epitaxy;

Polysilicon;

Ion

Implant; Gettering;

Crystal

Growing

HOME

Copyright

© 2004-Present

www.EESemi.com.

All Rights Reserved.