ESD Controls

The ESD

Association suggests focusing on just six basic principles for the

development and implementation of an effective

ESD control program,

namely, 1) ESD Immunity Design-in; 2) definition of the desired level of

ESD control; 3) identification of electrostatic protected areas (EPA's);

4) reduction, if not elimination, of static generation; 5) static

dissipation and neutralization; and 6) protection of products from ESD.

ESD Immunity Design-in

Prevention of

ESD-related problems starts with the ability to produce robust devices

that can withstand ESD events. This requires the proper determination of

the ESD sensitivity levels of new semiconductor devices prior to their

production release. This is best achieved by subjecting representative

samples of these devices to industry-standard ESD sensitivity tests

using an ESD sensitivity testing system (see example in Fig. 1).

There are several ESD sensitivity testing procedures available today,

each one depending on the ESD model being tested for. It is good

practice to test a device in terms of different ESD models. Devices that

exhibit inadequate immunity to ESD must be redesigned, if possible. This

is known as ESD immunity design-in.

|

|

|

Fig. 1.

An ESD/Latch-up Tester from KeyTek

|

Identification of EPA's

Aside from designing ESD

immunity into its products, a company must have a sound ESD control

program. To begin with, a company must identify all electrostatic

protected areas (EPA's) in its factory. An EPA is an area where ESD-sensitive

devices will be handled. Every EPA must be adequately protected by

ESD controls, the major ones of which are discussed below.

Static

Reduction/Dissipation/Neutralization

Over-all Grounding

The backbone

of static generation reduction and static dissipation is proper

grounding of everything a device touches. The primary means of grounding

ESD susceptible (ESDS) items (personnel, equipment, workstations, carts,

shelves, etc.) is to provide electrically conductive paths between these

items and a common ground.

Thus, every factory must have a

common

grounding point. Detailed

information on ESD grounding can be found in ESD Association standard

ESD-S6.1, Grounding-Recommended Practices.

Connecting everything to a

common ground point essentially

puts everything at the same potential (the potential

of the common grounding system). As long as everything is in equipotential balance, charging/discharging events will be prevented. It

is important to note though that insulators in an Electrostatic

Protected Area (EPA) cannot be grounded, so insulative materials must be

avoided in EPA's as much as possible.

ESD

Association Standard ANSI EOS/ESD 6.1-Grounding recommends a

two-step procedure for grounding equipment. The first step is to ground

all components of the work area (worksurfaces, people, equipment, etc.)

to the common ground, which is also referred to as the 'ESD common point

ground'. This ESD common point ground should be properly identified. ESD

Association standard EOS/ESD S8.1-1993 recommends its own symbol to

identify the common point ground.

The second

step is to connect the common point ground to the equipment ground or

the third wire (green) electrical ground connection. This is the

preferred ground connection because all electrical equipment at the

workstation is already connected to this ground. Connecting the ESD

control materials or equipment to the equipment ground brings all

components of the workstation to the same electrical potential.

If a

soldering iron used to repair an ESDS item were connected to the

electrical ground and the surface containing the ESDS item were

connected to an auxiliary ground, a difference in electrical potential

could exist between the iron and the ESDS item. This difference in

potential could cause damage to the item. Thus, any auxiliary

grounds (water pipe, building frame, ground stake) present and used at

the workstation must be bonded to the equipment ground to minimize

differences in potential between the two grounds.

Grounding of Personnel

People are

one of the primary generators of static electricity. The simple act of

walking around or repairing a board can generate several thousands of

volts on the human body. If not properly controlled or dissipated, the

accumulated static charge on a person can easily discharge onto a static

sensitive device. Such an event is known as human body model (HBM)

discharge.

Wrist

straps

are generally the primary means of controlling static charge build-up on

personnel. When properly worn and connected to ground, a wrist strap

keeps the person wearing it near ground potential. Because the person

and other grounded objects in the work area are at or near the same

potential, there can be no hazardous discharge between them. In

addition, static charges are safely dissipated from the person to ground

and do not accumulate.

|

|

|

Fig. 2.

Examples of wrist straps

|

Wrist straps

have two major components, the cuff that goes around the person's wrist

and the ground cord that connects the cuff to the common point ground.

Most wrist straps have a current limiting resistor molded into the

ground cord head on the end that connects to the cuff. The resistor most

commonly used is a one mega-ohm, 1/4 watt resistor with a working

voltage rating of 250 volts. This resistor would protect the person

wearing it from electric shock in case the point to which the wrist

strap is grounded accidentally gets 'live.'

Wrist straps

should be tested on a regular basis. Daily testing or continuous

monitoring is recommended.

|

|

|

Fig. 3.

Examples of wrist strap monitors

|

A second

method of controlling electrostatic charge on personnel is with the use

of

conductive floors

in conjunction with

conductive

shoes

or

foot straps.

Any charge build-up on a person wearing conductive shoes will be

dissipated to the conductive floors through the sweat layer between each

foot and shoe. The conductive floors must be properly grounded to

the common ground system.

In addition

to dissipating charge, some floor materials (and floor finishes) also

reduce triboelectric charging. The use of floor materials is especially

appropriate in those areas where increased personnel mobility is

necessary. When used as the primary personnel grounding system,

the resistance to ground including the person, footwear and floor must

be the same as specified for wrist straps (< 35 x 10E6 ohms) or the

voltage accumulation on a person must be less than 100 volts.

The use of

ESD-protective clothing is another way to control charge build-up on a

person.

Fig. 4.

Examples of heel and sole grounders, also known as foot straps

Fig. 5.

Conductive shoes and slippers

Grounding of Moving Equipment

Moving

equipment such as carts, chairs, and lifters can likewise easily

generate static charges. Thus, these moving equipment also need to be

grounded to the common ground. One way of doing this is by providing

these equipment with conductive wheels, casters, or drag chains that

creates an electrical path between the equipment and the conductive

flooring. Thus, moving equipment must only be used over conductive

floors, since this is the only way they can be grounded with a drag

chain or conductive wheels or casters.

Grounding Work Stations and Work Surfaces

A work

station must be equipped with materials and equipment to limit ESD

events. The key ESD control elements used in most work stations are:

1) properly grounded

static

dissipative surfaces;

2) a means of grounding personnel (usually a wrist strap); 3)

appropriate signage and labeling; and 4) air ionizers if there are

insulative materials in the work station. As usual, the static

dissipative surfaces and personnel grounding ports must be properly

grounded to the common grounding system.

Static

protective work surfaces must have a resistance to ground of 106

to 109 ohms to provide a surface that is at the same

electrical potential as other ESD protective items in the workstation.

They also provide an electrical path to ground for the controlled

dissipation of any static build-up on materials that contact the

surface.

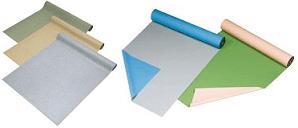

Fig. 6.

Examples of conductive mats and flooring

Grounding Production Equipment

Although

personnel-generated static is usually the primary source of ESD in many

environments, automated manufacturing and test equipment can also pose

an ESD problem. For example, a device may become charged from sliding

down an input track. If the device then contacts a grounded conductive

surface, a rapid discharge occurs from the device to the metal object.

Such a discharge is known as a Charged Device Model (CDM) ESD event.

Proper

grounding is the primary means of controlling static charge on

production equipment. Electrical equipment are required by the National

Electrical Code to be connected to the equipment ground (the green wire)

in order to carry fault currents. This ground connection can also serve

as a means to dissipate static charges on the equipment.

All electrical tools and equipment

used to process ESD sensitive hardware require the 3 prong grounded type

AC plug. Hand tools that are not electrically powered, i.e., pliers,

wire cutters, and tweezers, are usually grounded through the ESD-protective

work surface and the (grounded) person using the conductive tools.

Holding fixtures should be made of conductive or static dissipative

materials as much as possible. A separate ground wire may be required for

conductive fixtures not sitting on an ESD-protective work surface or handled by a

grounded person. Again, this wire must be connected to the common ground

system.

For those items that are composed of insulative

materials, the use of ionization or application of topical antistats may

be required to control the generation and accumulation of static charges.

Ionization

It is not possible to

eliminate all insulative materials

or isolated conductors that cannot be grounded from the production area. Thus, there

must be a way to control their ESD generation tendencies because these

items can not discharge to the common ground. Air ionizers serve this

purpose.

Air ionizers

neutralize the static charge on insulated and isolated objects by

charging the molecules of the surrounding air. Whatever static charge is

present on objects in the work environment will be neutralized by

attracting opposite polarity charges from the air. Because it uses only

the air that is already present in the work environment, air ionization

may be employed even in clean rooms where chemical sprays and some

static dissipative materials are not useable.

Air

ionization is just one component of a complete static control program.

It must not be a substitute for grounding or other methods.

Ionizers are used when it is not possible to properly ground everything,

or simply as a backup to other static control methods. In clean rooms, air

ionization may be one of the few methods of static control available.

The ionization

characteristics of air ionizers must be checked regularly, since an

improperly working air ionizer can emit a unbalanced stream of

positive and negative ions. If that happens, the air ionizer itself

would accelerate a static charge build-up, and be the root cause of a

serious ESD problem on the line.

Fig. 7.

Examples of bench-top ionizers

Fig. 8.

Examples of overhead ionizers

Protection of Products

from ESD

Packaging and Handling

ESD-sensitive

devices must never leave a plant unless they are properly protected from

ESD. Direct protection of devices from ESD can be provided by properly

selected packaging materials such as antistatic bags. Even intra- or

inter-factory transport of devices must be done with the use of ESD-protective

carriers.

ESD-protective packaging

materials must: 1) be dissipative; 2) exhibit low triboelectric charging

tendency; and 3) have the ability to shield their contents from

electrostatic fields.

The insides of these packaging materials have a low charging layer, while

their outer layers have a surface resistivity that's within the dissipative

range.

Dissipative

materials have a surface resistance greater than 104

but less than or equal to 1011 ohms when tested according to

EOS/ESD-S11.11 or a volume resistivity greater than 1.0 x 105

ohm-cm but less than or equal to 1.0 x 1012 ohm-cm when

tested according to the methods of EIA 541.

Electrostatic

shielding attenuates electrostatic fields on the surface of a package in

order to prevent potential differences from being developed inside the

package. Electrostatic shielding is provided by materials that have a

surface resistance equal to or less than 1.0 x 103 when

tested according to EOS/ESD-S11.11 or a volume resistivity of equal to

or less than 1.0 x 103 ohm-cm when tested according to the

methods of EIA 541. ANSI/ESD 11.31 is used to evaluate the shielding

characteristics of bags.

Fig. 9.

Examples of ESD-protective bags

Identification of ESD-sensitive Devices

The

final element of a good static control program is the use of appropriate

symbols to identify ESD-sensitive devices and assemblies, as well as

products intended to control ESD. The two most widely accepted symbols

for identifying ESDS parts or ESD control materials are defined in ESD

Association Standard ANSI ESD S8.1-1993 - ESD Awareness Symbols.

See Also:

What is ESD?;

ESD Models; ESDS Levels;

ESD Failures;

ESD Standards;

ESD Audit Checklist

Home

Copyright

©

2001-2005

www.EESemi.com.

All Rights Reserved.